The circular economy offers organisations a systematic way of solving some of the biggest problems of the world today. The economic model focusses on extending the value of existing raw materials and products to mitigate the impacts of materials extraction. It also prioritises the use of renewable energy over fossil fuels to help curb carbon emissions in many industries.

Far from being a recent invention, the concept of circularity has been around for a very long time. Societies have been experimenting with cycles and feedback loops in production for thousands of years. However, it was not until the advent of global crises, such as climate change and biodiversity loss, that CE solutions became widely accepted.

Now, more governments and businesses have started to adopt the circular economy approach. The future of many industries depends on how they can effectively use the finite resources available in the world.

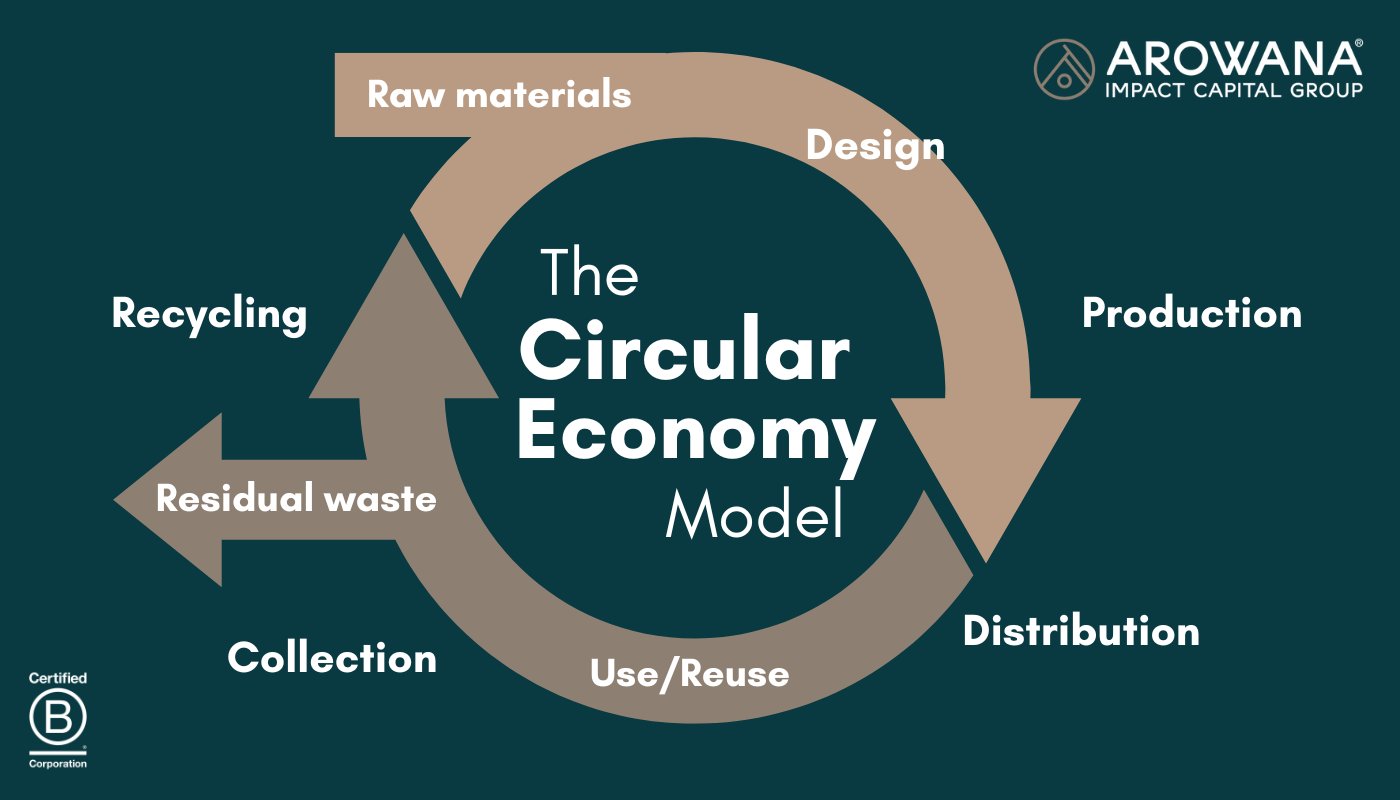

A circular economy (CE) is an economic system that makes use of restorative or regenerative industrial processes and economic activities. The objective is to preserve the value of raw materials, components, and products as much as possible. This is done through sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials.

In a CE, manufacturers try to reduce waste to a minimum. When a product reaches its end of life, the materials used to make it are kept within the economy wherever possible. Further value is created by using the materials productively again and again.

Many organisations view the circular economy as a potential solution to global challenges. The Ellen McArthur Foundation, for example, believes it can provide society with the means to address biodiversity loss and climate change, while also tackling important social needs.

Researchers often point to three main elements that a circular economy needs to focus on to be effective: closed cycles, renewable energy, and systems thinking.

Circular economies place heavy emphasis on closing material cycles. During the manufacturing process, every residual stream is used to make a new product so that no waste is left. Residual flows are often segregated between biological and technical cycles. Toxic substances are also taken out of production.

In a CE, businesses take back the products from customers after use. This allows them to repair the used items and give them a new useful life. For this system to work, products, components, and raw materials should be kept in high quality.

Another key element of circular economies is their use of renewable energy. Just like with raw materials, CE businesses prioritise extending the value of energy resources as well. This means sustainable power sources like solar, and wind are preferred over fossil fuels.

The concept of circularity can also be used in the production of renewable energy materials and equipment. By using existing materials within the economy, manufacturers can minimise the extraction of new raw materials. This, in turn, can help reduce the negative impacts of such activities on the climate, biodiversity, and society.

Systems thinking also plays a key role in the effectiveness of circular economies. Every person, company, and organism included in the system is connected to each other. This means every action that one stakeholder takes can affect other members of the network.

In a circular economy, every single decision should always consider its short-term and long-term consequences. Stakeholders should also factor in the potential impact of each action on the entirety of the value chain.

The concept of circular economy was developed as a more sustainable alternative to the traditional linear economy model.

In LE, manufacturers follow a “take-make-dispose” strategy where they collect raw materials and turn them into products. These products will be used until they reach their end of life and are discarded as waste. To create value, businesses would have to produce and sell as many products as they possibly can.

On the other hand, CE follows the 3R (reduce-reuse-recycle) strategy. Companies prioritise minimising the use of resources, maximising the reuse of products, and finding new uses for raw materials. Circular economy businesses focus on preserving the value of products instead of producing and selling as many as possible.

Circular and linear economies also have different approaches to sustainability. LE focusses on eco-efficiency, where the economic gain of production is maximised while also minising its environmental impact. By reducing the negative impact per economic profit gained, businesses can manage the potential overload of the system.

Meanwhile, CE focusses on enhancing the eco-effectivity of the system to achieve sustainability. By adopting radical innovations and system change, companies are able to maximise the positive impact of the system.

This difference between eco-efficiency (linear economy) and eco-effectivity (circular economy) can best be observed in the production of beef. One of the biggest challenges to raising cattle is the high levels of greenhouse gas (methane) emissions it produces.

To solve this issue, a linear economy would look at the way the cows are being fed and try to change it. Altering the type or amount of food the animals are given would allow cattle raisers to reduce methane emissions. This would essentially make beef production more eco-efficient.

However, a circular economy would address the GHG emission problem by not making beef from cows at all. Companies would rather develop a plant-based meat alternative that they can offer to consumers. By using plants instead of animal meat, CE businesses would help promote biodiversity, employment, and landscape management. This would make the ‘beef’ production eco-effective.

A circular economy offers several advantages to both companies and consumers, making an appealing production and economic model. These benefits can be divided into environmental, economic, and business.

With its strong focus on sustainability, circular economies prioritise the preservation of ecosystems and natural resources. One example is companies’ heavy emphasis on limiting their greenhouse gas emissions.

By using renewable energy instead of fossil fuels, manufacturers can cut the amount of GHG that they emit. It also improves production since renewables like solar and wind power are much more energy-efficient than petrol.

CE businesses also try to optimise their use of raw materials and agricultural productivity. Through reusing and dematerialising, companies can rely on fewer materials and processes to create products.

Switching to a circular economy model today can help organisations significantly reduce their overall carbon levels. A 2015 report found that CEs have the potential to halve their CO2 emissions by 2030, relative to 2018 levels. It showed a 48% reduction in emissions across mobility, food systems, and the built environment. This number could grow even further to 83% by 2050.

In the agriculture sector, the CE model can help improve the health and resilience of farmlands through composting. Farmers use anaerobic processes to ensure that important nutrients used in food production are returned to the soil. They also lower the number of residues that the farmers need to address to keep the soil viable.

Some circular economies have begun diversifying crops in their farmlands to improve soil health. This allows local insect populations to thrive, which also benefits other species that are part of local food chains.

Regenerative farming techniques such as these provide important habitats for microorganisms at the beginning of the food chain. They help hold more water in the soil, resulting in better fertility and productivity of farmlands.

The CE model’s focus on sustainable food and goods production also leads to better growth for economies overall. By eschewing the take-make-dispose strategy of the linear model, CEs can use and reuse natural capital more efficiently. They also find more value throughout the life cycle of existing products.

Many manufacturers still follow the linear economy model. Many of them assume that there will always be a constant supply of natural resources. However, the take-make-dispose mentality of LE businesses has led to severe natural resource depletion.

Ninety percent of global biodiversity loss and water stress are caused by resource extraction, according to the World Economic Forum. The practice also contributes to more than half of global climate change impacts.

The extraction and processing of metals and non-metallic minerals produce about 20% of greenhouse gas emissions. The production of plastics and other materials also adds to the increase in GHG levels. Current energy technology solutions can only do so much to mitigate these negative effects.

Circular economies develop smarter ways to use natural resources. By fully recycling raw materials used in production, it minimises the need to extract and process new resources. Recycling also cuts the number of materials that go to waste when they reach their end of life.

Transitioning to a circular economy model also creates better employment opportunities for workers. CE businesses are often in need of designers and engineers who can develop new ways of recycling and repairing materials. This focus on innovation also leads to the creation of new business models.

Additionally, a World Economic Forum report suggests that circular economies can bring greater local employment, particularly in entry-level and semi-skilled jobs. These jobs can help solve some of the economic problems that many developing countries face. However, these benefits depend on whether labour markets can be better organised and regulated.

Indeed, several international organisations are optimistic about the potential of CEs for employment generation. According to an International Institute for Sustainable Development (IISD) report, an estimated 3.9 million people found jobs because of the circular economy.

The International Labour Organization (ILO) believes 18 million green jobs can be created through the CE model by 2030. Meanwhile, Global Climate Action Summit projects that more than 65 million new low-carbon jobs by 2030.

A circular economy also leads to new profit opportunities. Businesses can increase their earnings by cutting their waste and energy costs through circularity. They can also improve the continuity of their supply.

Adopting circular methods can also help companies enter new markets that would not have been available had they still been in a linear economy.

For manufacturers, making sure that they receive a steady supply of raw materials is of the utmost importance. Without these, they wouldn’t be able to produce products to meet the demand.

However, several factors make it difficult for many businesses to secure their supplies. The availability of raw materials often drives up prices, making them highly volatile to depend on. Natural calamities and geopolitical crises can also severely affect supply chains.

Instead of relying on the procurement of new raw materials, CE businesses address the supply issue by cutting the number of materials they use overall. They create products made from recycled or reused materials instead. This reduces their dependence on volatile raw material prices.

Ultimately, the circular economy model helps companies become more resilient against disruptions in supplies.

With the CE model opening up new business opportunities, companies will need to create additional services to meet the demand. The Ellen McArthur Foundation outlines three examples of these new services:

The report explained that specialised knowledge involves the collection, disassembly, refurbishment of products, integration into the manufacturing process, and introduction of the products to the market.

In many cases, companies can adopt these new services by creating subsidiaries.

Despite the numerous benefits of a circular economy, many countries have yet to adopt this economic model. Businesses face several challenges that prevent them from switching their production strategy.

According to the World Economic Forum, there are 5 main barriers against the circular approach.

Many businesses still don’t have enough knowledge about available CE solutions or how to apply them. Some may already have the know-how but don’t necessarily have the competencies to implement such strategies.

Another challenge is the absence of a circular mindset in business owners. Many companies still view post-consumer products as mere waste. There are also those that don’t consider the sake of other stakeholders beyond their immediate customer base.

CE adoption is also hampered by the refusal of some businesses to even consider the potential of the model for innovation.

Unfortunately, only a few companies appreciate the financial benefits of switching to a circular economy. There are businesses who flat-out refuse to invest in CE solutions that would cost more than what the organisations could afford.

Some companies also believe that they might lose their competitive edge if they were to switch to a different market.

For bigger companies, adopting a CE model may not be that difficult since they could easily shift to recycled or reused materials. However, this might not be as simple for smaller manufacturers that rely heavily on certain raw materials.

Recycled or reused materials or components are still not yet readily available on the market. This makes it harder for companies to source enough materials for their production. Those that are available might not meet the right quality or are far too expensive for manufacturers.

There are also several other factors that keep companies from adopting circular approaches. Business owners are uncertain about the stability of regulations (such as carbon tax), as well as the viability of CE-related technologies (such as components reuse).

Some companies are also unsure whether customers would be willing to accept a switch to a circular economy. CE solutions cannot always be used as an alternative to non-CE practices since they don’t necessarily have the same quality or price level. This financial uncertainty leads many business owners to be wary of changing from a linear to a circular model.

Switching to a circular economy requires a significant change in consumer behaviour. It will make it difficult for people to buy into the CE model if they would have to put in more effort in doing so.

Also, not all companies can shoulder the high operating cost involved in implementing CE approaches. This can discourage even those who might be convinced of the potential benefits of these solutions.

There is also a need to create market-wide standards in implementing circular economy approaches. Some solutions, such as the reduction of material variation, can only effectively improve circularity if many companies in a given market adopt the measure.

Throughout the years, the circular economy model has been adopted in different industries. Companies have found various innovative ways on how to apply circularity in their businesses.

Some clothing brands have started leasing their products instead of selling them. The approach builds on the concept of ‘sharing economy’, where access and services are prioritised over ownership. This allows the manufacturer to retain ownership of their products and keep the items within their production cycle.

For these companies, they take on the role of the manufacturer and recycler of the products. Not only does it extend their own responsibility for the items, but it also lets them produce more circular clothing.

Circularity in clothing is viewed as a significant step toward reducing waste. The UN Conference on Trade and Development (UNCTAD) identified the fashion industry as the second most polluting in the world.

The consumer tech industry is also adopting the CE model by offering leasing services for mobile devices. Some telecom companies allow customers to lease mobile phones instead of buying them.

The circular service lets the company keep a closed cycle for the recycling and reuse of products. More than 99% of mobile phones are returned. About 95% of these devices are then either repaired and reused or recycled by the telecom company. This allows the industry to cut as much as 50kg of carbon dioxide for each mobile device saved.

Single-use plastics have also been a particular concern in terms of waste management. To address the problem, several restaurants have started using environmentally friendly containers for food items. These include cardboard packaging, cloth bags, and even recycled containers that were once used for another product.

Some food stores have switched to using biodegradable utensils and even tried using edible cups, straws, and plates.

In the construction industry, more businesses around the world are now incorporating reused or recycled items in materials. Some have developed new technologies that use recovered plastics to produce eco-bricks. This helps reduce the number of plastic waste that could end up overcrowding landfills.

One example of this is Green Antz Builders, an environmental solutions company in the Philippines. Green Antz collects used plastics and turns them into eco-friendly construction materials. The company has also tapped local businesses and communities to donate their plastic waste, such as beverage bottles, tarpaulins, and CDs/DVDs.

Despite the potential of the circular economy to solve many of the world’s problems, it still suffers from the same limitations as other economic models. Its solutions can only be fully effective if a large portion of society adopts and implements them.

Every stakeholder in the economy needs to do their part to maximise the value of finite resources and reduce the production of waste. Circularity, in this sense, can only work if every single link is connected.

For more information on the circular economy, visit the Arowana Impact Capital website.